Products

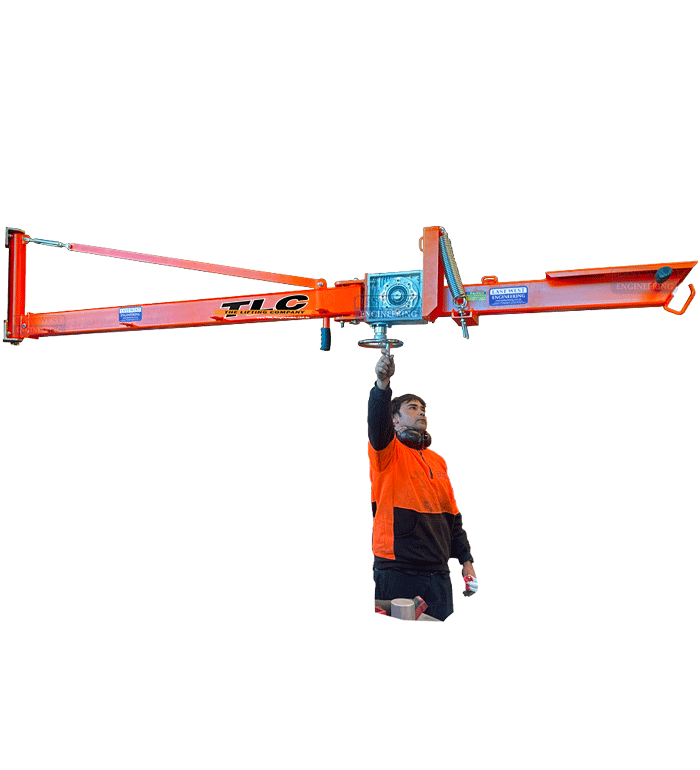

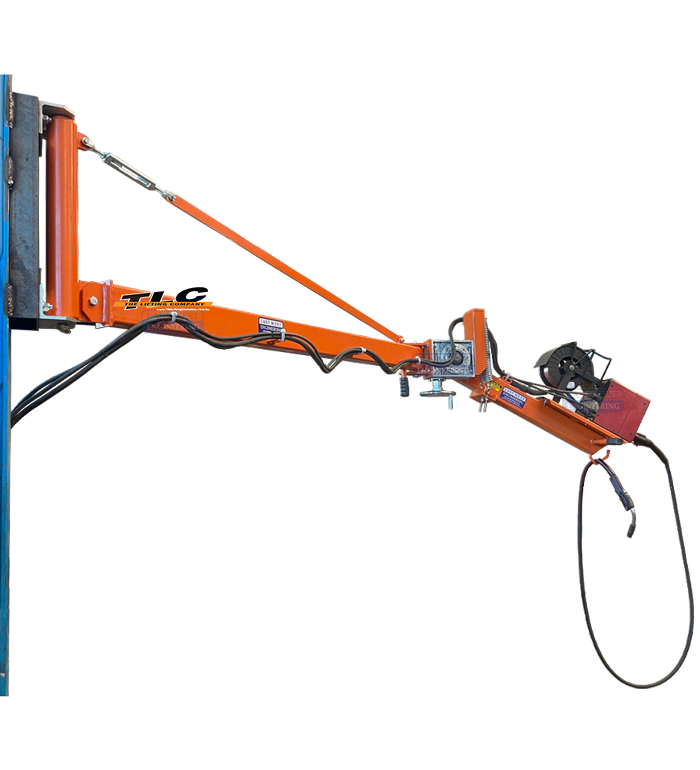

The AWB36 Welding Boom is designed to increase welding productivity and safety by allowing full coverage of the welding area and removing trip hazards and floor clutter. The double articulated arms provide greater control over the welding process to help improve welding quality and efficiency. The operator can adjust the angle of the secondary arm by cranking the worm gearbox to ensure optimal gun position, ideal for reducing welder fatigue and strain. A tiltable boom angle brings the wire feeder to an optimal working height allowing maintenance or changing of the wire roll without the need for the operator to use a ladder.

FEATURES:

• Long 3.38m boom

• Double articulated arms allow greater flexibility, manoeuvrability and coverage

• Manually tracked boom arms move effortlessly with the operator

• 180° bi-directional rotation of both primary and secondary arms

• Secondary arm raises and lowers 776mm (45°) for optimal welding gun positioning

• Tilt controlled via a worm drive gearbox for fast and simple manipulation of boom angle

• Adjustable spring balanced design allows for the weight of different wire feeders to be counter balanced within the tilt range

• Tiltable boom allows ease of maintenance or wire roll change without a ladder

• Large mounting plate to suit various wire feeders

• Tie points fitted to secure power cables

• Top strut fitted with turn buckle to allow leveling of assembly

• Wall mount brackets supplied

• Optional post (AW-POST) available for floor mounting

• Reduces welder fatigue, strain and non-arc time welding related activities

• Design & engineered to relevant Australian Standards

• Enamel paint finish

Supplied part assembled (in 2 sections) for simple on-site installation

|

Working Load Limit (WLL) | 50kg |

| Boom Arm Reach | 3385mm (primary 2110mm / secondary 1275mm) | |

| Arm Rotation | 180° bi-directional | |

| Secondary Arm Tilt | 776mm (45°) | |

| Unit Weight | 100kg |

|

Mounting plate may require drilling to suit wire feeder.

Wire feeder and welding equipment not included |